Dust Collection Systems

Jardar Systems, Inc. offers many high quality Dust Collection Systems to reduce costs and provide consistency to each of your projects. Learn about our variety of Dust Collectors below.

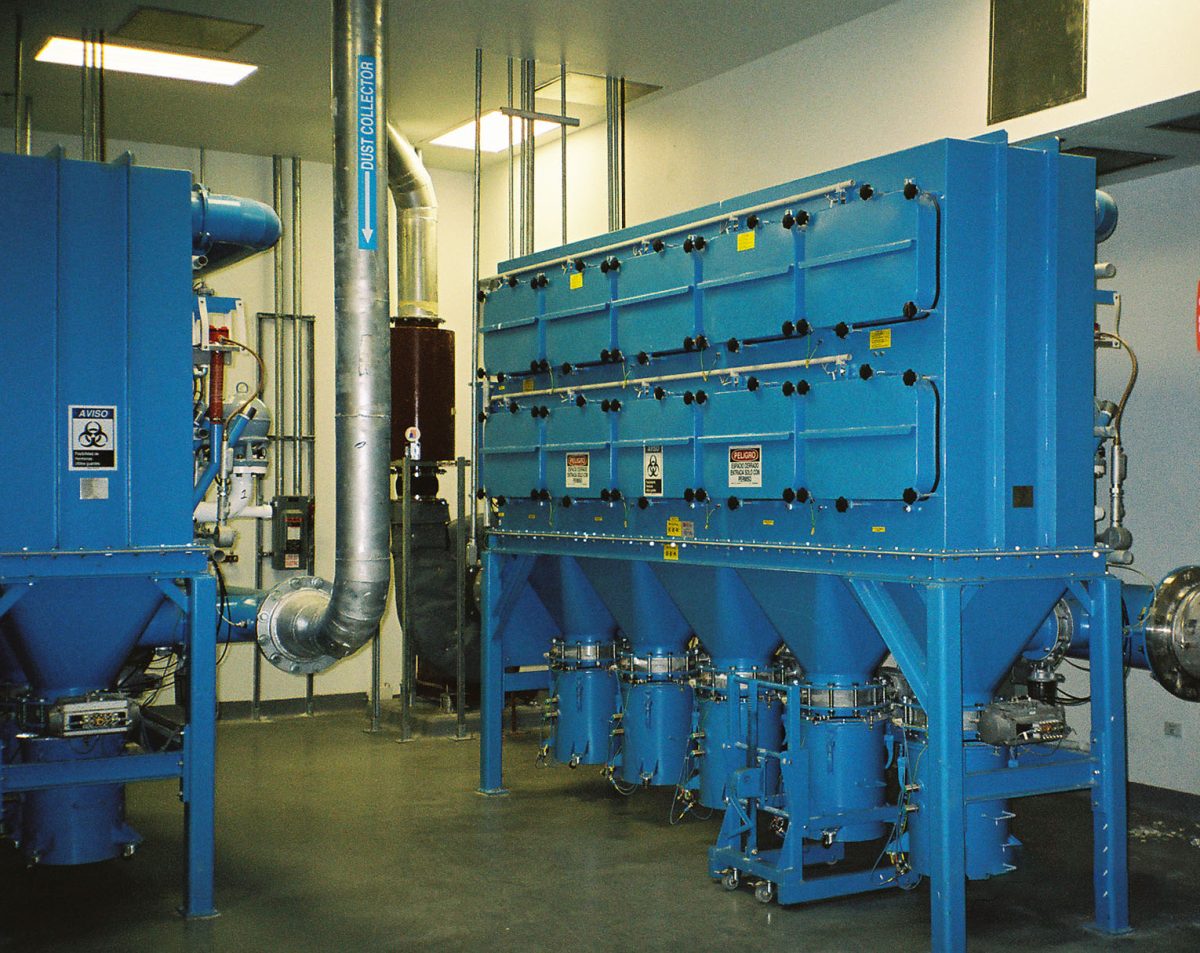

Baghouse Dust Collectors

Jardar Systems proudly offers Baghouse Dust Collectors. This superior product includes many standard value-added features such as larger inlet diffusers to prevent hopper turbulence and re-entrainment thereby facilitating particulate removal. These products reduce unnecessary dust load and offer a “clean-on-demand” control system complete with integral pressure switches and gauges to initiate the required cleaning cycle.

Baghouses are used for control of:

De-Dustable HEPA Filters

HEPA stands for, “High Efficiency Particulate Air.” A HEPA filter is capable of removing 99.97% of dust, pollen, mold, bacteria, and any airborne particles with a size of 0.3 microns or greater. The, “Bag-In/Bag-Out,” design of these HEPA filters keeps hazardous particulate in the dust collector and away from operators and maintenance personnel during filter change-out. Also, these HEPA filters can be supplied with a pulse jet mechanism that removes the dust from the filters during operation and extends the life of the HEPA filter.

Cartridge Collectors

Jardar Systems designs and engineers industrial cartridge-type dust collectors for explosive, high vacuum, or high pressure environments. These units are fabricated per ASME standards to 150 PSIG or higher pressures. These pulse-jet dust collectors are specifically designed for explosive dusts and gases.

Cartridge Collectors are used for control of:

Dust Cyclones

Cyclone Dust Collectors are used in industrial environments for the separation of larger (>20 microns) particles from air streams. Ceramic-lined dust cyclones are especially useful removing large particulate abrasive dust from an air stream, which can then be easily recycled back to the plant.

Some Typical Applications For Dust Collectors:

Typical Industrial Users:

Emissions:

Schedule a Consultation Today and Let’s Discuss Which Dust Collector is Best for Your Needs

Schedule an in-depth consultation with us to discuss your requirements and specifications. Our team of engineers and designers can assess your needs and deliver a dependable, cost-effective solution. Call us today at (847) 550-1686 or fill out our online form.