Demister Systems

Jardar Systems, Inc. proudly brings you our custom-built mist eliminators. Learn about our Demister Systems for mist removal and how they can offer a solution for your daily operation.

Principles of Operation

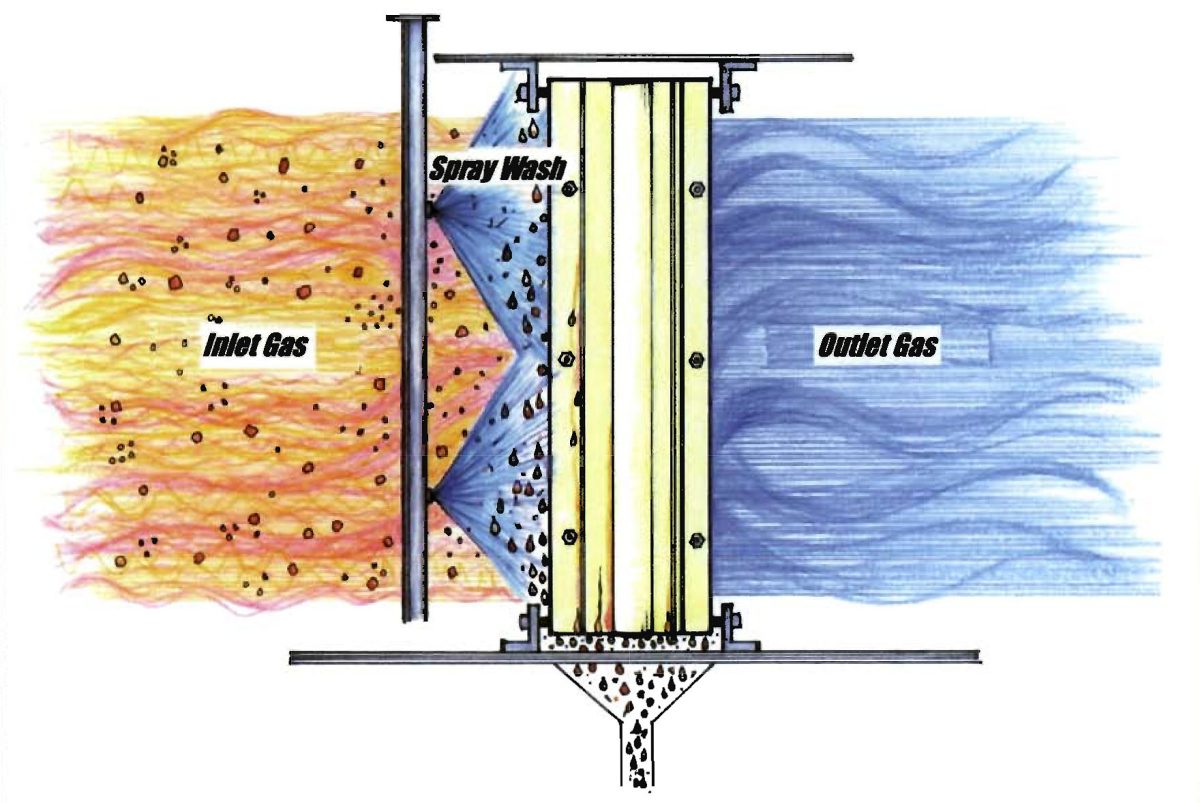

Through the principles of impaction and interception, the free-water droplets in the gas stream encounter the leading edges of the vanes. As the gas stream abruptly changes direction several times through the vanes, the entrained dust and mist continue in a straight line impacting on the vanes. Also, dust and mist intercept one another in the gas stream, growing larger and facilitating the impaction process. The particulate-laden liquid flows down the vanes assisted by an intermittent or continuous wash-down into the drain trough. The vanes produce droplet-free air on the back end of the demister system.

How Our Mist Removal Systems Work:

Chevron Vanes

Chevron vanes use a 3-pass design to remove water droplets and particulate from a gas stream. The 3-pass chevron system is normally used where heavy particulate loading and standard gas stream velocities are found. The addition of an engineered wash-down system assists in the removal of particulate from the vanes and inhibits build-up of material on the vanes.

Chevron vanes are available in Stainless Steel, Hastelloy, Monel, Inconel, and polypropylene. Depending on the specific design considerations, other materials of construction can be supplied.

Half-Wave™ Vanes

Half-Wave™ vanes are proprietary high-performance demisters incorporating engineered drain channels and troughs. These specifically-designed vertical elements allow the Half-Wave™ vanes to de-mist a gas stream at much higher velocities than standard vane configurations without re-entraining droplets in the gas stream. A properly designed wash-down system assists in the removal of particulate from the vanes and inhibits material build-up on the vanes.

Half-Wave™ vanes are available in high temperature polypropylene. Depending on the specific design considerations, other materials of construction can be supplied.

Vane Applications:

Process Applications:

Our Demister Systems Work For a Variety of Industries

Our Mist Eliminators are designed to assist in the following industry applications:

Jardar Systems Offers Exceptional Engineering Services

Jardar Systems, Inc. designs, engineers, and supplies complete solutions to meet your strictest air pollution control requirements. Equipment is custom designed using the latest in process and mechanical engineering technology and software. Through our affiliations with foreign companies, engineering and equipment can be supplied the world over.

Let’s Schedule a Consultation to Discuss Your Demister System

Schedule an in-depth consultation with Jardar Systems, Inc. today so we can discuss detailed specifications. This way, our team of engineers and designers can assess your needs and deliver a dependable, cost-effective solution. Call us today at (847) 550-1686 or fill out our online form to speak with a mist removal system specialist. We look forward to speaking with you!